Casella UK

Wolseley Rd, Kempston,Bedford MK42 7JY

+44(0)1234844100

info@casellasolutions.com

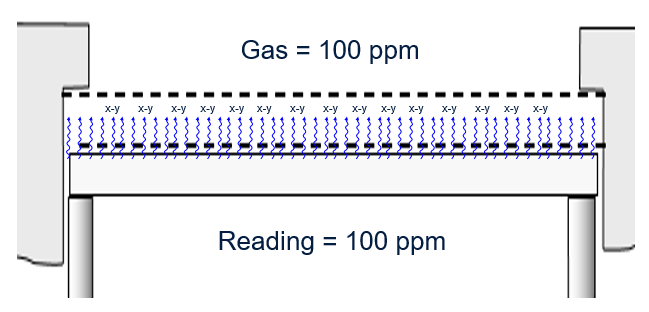

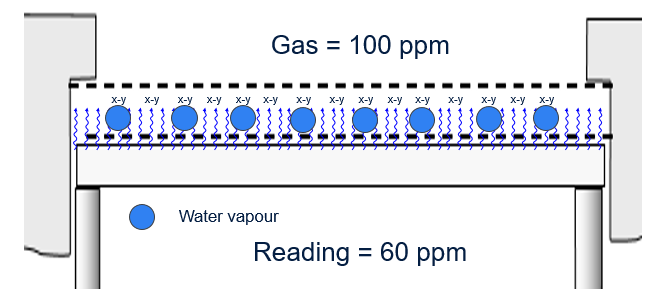

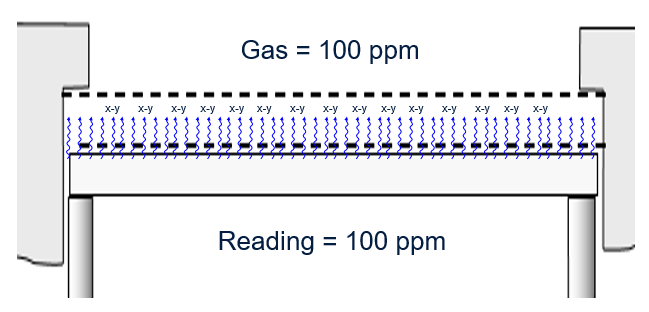

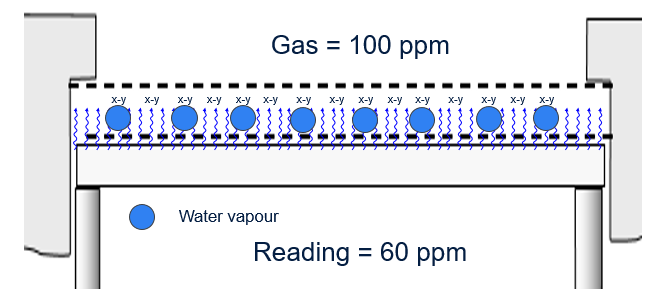

Figure 2: Cross section of a PID sensor with and without water vapour present

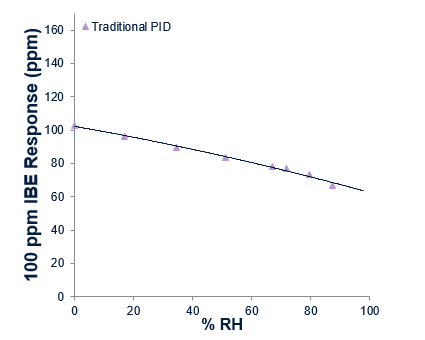

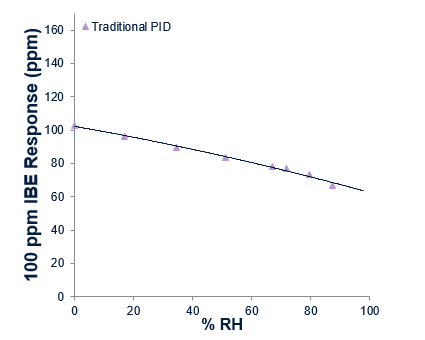

Figure 3: Effect of water vapour absorption

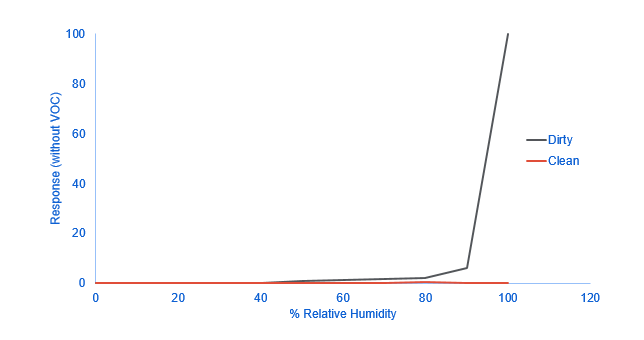

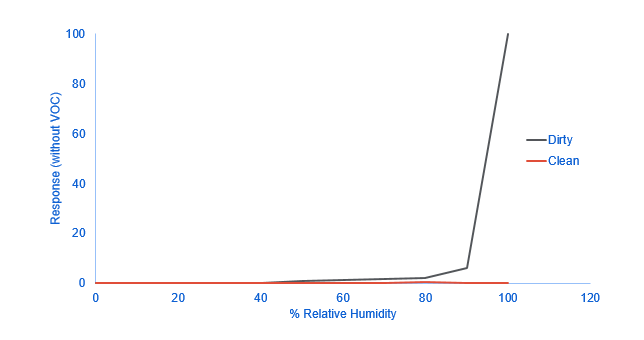

Figure 4: Effect of contamination

Like many sensors and measurement instrumentation, traditional PIDs can be affected by the environmental conditions such as those found in outdoor environments, in particular dirt and humidity. Humidity is a naturally occurring phenomenon and is present in the atmosphere and gasses. The presence of humidity can disrupt PID measurements in two ways leading to false low or conversely high readings.

The cause of low readings is because water vapour absorbs the photons normally released by photoionization as can be seen in the simplified cross section of a PID sensor (figure 2). The effect worsens with increasing humidity as shown by figure 3.

Contamination can also build up between the electrodes (shown as dotted lines in figure 2) effectively short circuiting them, leading to a high, ‘false positive’ reading at high humidity with no VOC present i.e. greater than 90% relative humidity. The dramatic effect can be seen in figure 4.

Clearly both these effects are unacceptable in potentially safety critical applications.

Conventional PIDs may use humidity suppression/compensation techniques but each of them has disadvantages:

- Humidity sensor - these typically have a slower response than the PID sensor itself which casuses a drifting compensation

- Desciccant tube - these both slow the PID response and also reduces it by adsorption, plus they need replacing from time to time which adds cost

- Himidify the calibration gas - this only works at one level of humidity and is no longer accurate when the humidity changes

Importantly none of these solutions solves a false positive at high humidity. Looking at the proprietary PID (figure 1 - noted in Part 1 here), the presence of the porous membrane should be noted. In this design it is made from a hydrophobic material which means that it rejects the ingress of water vapour and mitigates the chance of low readings. To deal with high humidity, the addition of a patented third, fence electrode overcomes the possibility of incorrect high readings since it behaves as a conductive break and stops the excess current flow caused by the presence of high humidity which would otherwise lead to a false positive.

Casella has used its expertise in a number of disciplines to system integrate a growing number of sensors for the accurate measurement and remote monitoring of physical and chemical agents that can impact on the health and wellbeing of people and the environment. The benefits of a plug and play approach mean simple installation and readily available online data and reports from any location.

Figure 2: Cross section of a PID sensor with and without water vapour present

Figure 3: Effect of water vapour absorption

Figure 4: Effect of contamination

Contamination can also build up between the electrodes (shown as dotted lines in figure 2) effectively short circuiting them, leading to a high, ‘false positive’ reading at high humidity with no VOC present i.e. greater than 90% relative humidity. The dramatic effect can be seen in figure 4.

Clearly both these effects are unacceptable in potentially safety critical applications.

Conventional PIDs may use humidity suppression/compensation techniques but each of them has disadvantages:

- Humidity sensor - these typically have a slower response than the PID sensor itself which casuses a drifting compensation

- Desciccant tube - these both slow the PID response and also reduces it by adsorption, plus they need replacing from time to time which adds cost

- Himidify the calibration gas - this only works at one level of humidity and is no longer accurate when the humidity changes

Importantly none of these solutions solves a false positive at high humidity. Looking at the proprietary PID (figure 1 - noted in Part 1 here), the presence of the porous membrane should be noted. In this design it is made from a hydrophobic material which means that it rejects the ingress of water vapour and mitigates the chance of low readings. To deal with high humidity, the addition of a patented third, fence electrode overcomes the possibility of incorrect high readings since it behaves as a conductive break and stops the excess current flow caused by the presence of high humidity which would otherwise lead to a false positive.

Casella has used its expertise in a number of disciplines to system integrate a growing number of sensors for the accurate measurement and remote monitoring of physical and chemical agents that can impact on the health and wellbeing of people and the environment. The benefits of a plug and play approach mean simple installation and readily available online data and reports from any location.